Scaffolding Solutions

Safe and reliable scaffolding for all your construction projects

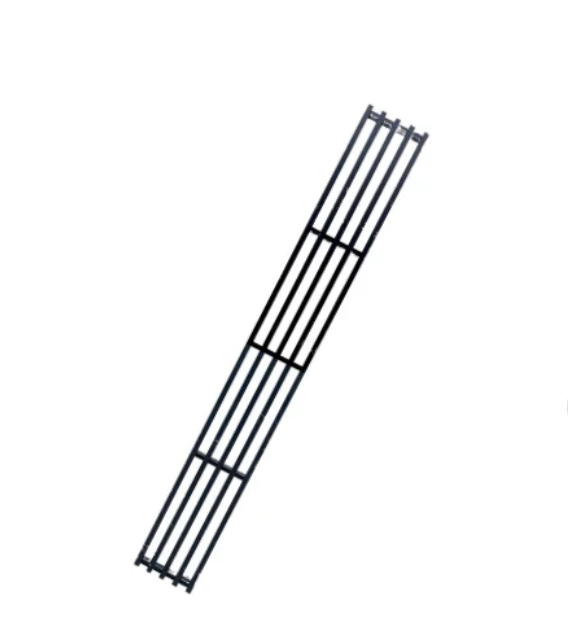

Cuplock System

The Cuplock System is a highly popular and versatile modular scaffolding system widely used in construction and industrial applications. Known for its efficiency, safety, and ease of assembly, this system employs a unique locking mechanism that simplifies the assembly process, ensuring a secure and stable scaffold structure. The Cuplock System comprises vertical standards, horizontal ledgers, and diagonal braces, all interconnected through a cup-and-cone locking system.

Key Features

Technical Specification

Benefits

Products

Product Applications

Construction Sites

Ideal for building and maintaining structures, including high-rise buildings, bridges, and industrial plants.

Maintenance Work

Useful for accessing and repairing tall structures or equipment.

Formwork Support

Provides support for formwork in concrete construction, ensuring proper alignment and stability.

Shoring

Offers support for temporary structures and load-bearing during construction activities.

Event Staging

Suitable for constructing stages, viewing platforms, and other temporary structures for events and performances.